- Deutsch (de)

- English (en)

The idea for the following circuit actually arose from the consideration that in addition to recording the consumption of the domestic heating system (here gas), it would also be very interesting to also record the outside and inside temperature. After all, the colder the weather, the more Ito heat. You may already have a temperature measurement system in use at home in the form of a weather station. So why not 'tap' into the wireless transmission of these sensors …

Incidentally, the above-mentioned energy collection (including electricity and water) is done using the free smart meter approach from http://www.volkszaehler.org. But more on that later.

The device should therefore receive and understand the IT+ sensor protocol and deliver the measured values recorded in this way to the smart meter via Ethernet on the intranet or internet. In order to be able to record independently of a network, a microSD interface for data storage would be a nice gimmick. Summarized again:

If you dare to use the IT+ protocol, you will find some sources (see links). The sensor always send every 4.5 seconds 5 bytes. The radio frequency is fixed at 868MHz. If the sensor can also measure the humidity, the value comes with it, if not then there is a fantasy value (= 106). Each sensor has an address coding. Caution there are sensors that use a new address after the battery has been changed. Several sensors can also be evaluated in parallel decoding the address. It should also be noted that no negative values are transmitted, as the temperature is always treated with an offset of 40 before transmission.

// ##### IT+ Frame ##### // Frame example (5 byte): // 92h 03h 94h 59h 3Ch --> Addr:32, Temp:-0.6, Hygro:89.0 // 92h 86h 24h 28h DEh --> Addr:40, Temp:22.4, Hygro:40.0 // | || | || || || // 9 28 624 28 DE // | | | | +--> CRC-8 (x8 + x5 + x4 +1) // | | | +------> Hygro in % // | | | bit6..0 = hygro value (0..127, 106 = no hygro) // | | | bit7 = weak battery indicator (0=okay, 1=weak) // | | | example: 28 --> hygro 40%, battery okay // | | +-----------> Temp (T+40)*10 in °C // | | nibble 1 = T10 // | | nibble 2 = T1 // | | nibble 3 = T0.1 // | | example1: 624 --> 62.4 - 40 = 22.4°C // | | example2: 394 --> 39.4 - 40 = -0.6°C // | +----------------> SensorID // | bit7..2 SensorID (0..63) // | bit1 = Restart flag (0=no restart, 1=restart-->new batt) // | bit0 = unused (always 0) // +------------------> Message length (number of nibbles that follow) // example: 9 --> 9 nibbles follow

The following components are used in the hardware:

There is an inexpensive 868MHz RFM12 module for receiving (and, if you want, also for sending).

It is a Universal ISM Band FSK Transceiver and has already been extensively described elsewhere RFM12.

Communication takes place via a normal SPI interface in 16-bit transfer. The setting options are so versatile that you get desperate at the beginning until you finally are able to receive. Therefore, here is the init sequence that was successful for me:

// Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 // ← 1 0 0 0 0 0 0 0 el ef b1 b0 x3 x2 x1 x0 0x8008 // 1 0 0 0 0 0 0 0 1 1 1 0 0 1 1 1 0x80E7 rf12_trans(0x80E7); // ena TX latch, ena RX FIFO, 868MHz, 12.0pF // 1 0 0 0 0 0 1 0 er ebb et es ex eb ew dc 0x8208 // 1 0 0 0 0 0 1 0 -------- do on the fly --------- // ← 1 1 0 0 1 1 0 0 0 ob1 ob0 lpx dly dit bw1 bw0 0xCC77 // 1 1 0 0 1 1 0 0 0 1 1 1 0 1 1 1 0xCC77 rf12_trans(0xCC77); // drv 5/10MHz, low-power OSC, no dith., band width 256kB // ← 1 1 0 0 0 0 0 0 d2 d1 d0 v4 v3 v2 v1 v0 0xC000 // 1 1 0 0 0 0 0 0 0 1 0 0 1 0 0 1 0xC049 rf12_trans(0xC049); // 1.66MHz, 3.1V // ← 1 0 1 0 f11 f10 f9 f8 f7 f6 f5 f4 f3 f2 f1 f0 0xA680 // 1 0 1 0 0 1 1 0 0 1 1 1 1 1 0 0 0xA67C rf12_trans(0xA67C); // FREQUENCY 868.300MHz // ← 1 1 0 0 0 1 1 0 cs r6 r5 r4 r3 r2 r1 r0 0xC623 // 1 1 0 0 0 1 1 0 0 0 0 1 0 0 1 1 0xC613 rf12_trans(0xC613); // DATA RATE 17.241 kbps // ← 1 0 0 1 0 pi d1 d0 i2 i1 i0 g1 g0 r2 r1 r0 0x9080 // 1 0 0 1 0 1 0 0 1 0 1 0 0 0 0 0 0x94A0 rf12_trans(0x94A0); // VDI, fast, 134khz, LNA 0dB, DRRSI -103 dB // ← 1 1 0 0 1 1 1 0 b7 b6 b5 b4 b3 b2 b1 b0 0xCED4 // 1 1 0 0 1 1 1 0 1 1 0 1 0 1 0 0 0xCED4 rf12_trans(0xCED4); // SYNC=2DD4 // ← 1 1 0 0 0 0 1 0 al ml 1 s 1 q2 q1 q0 0xC22C // 1 1 0 0 0 0 1 0 1 0 1 0 1 1 0 0 0xC2AC rf12_trans(0xC2AC); // autolock, dig. filter, mid level // ← 1 1 0 0 1 0 1 0 f3 f2 f1 f0 sp al ff dr 0xCA80 // 1 1 0 0 1 0 1 0 1 0 0 0 0 0 1 1 0xCA83 rf12_trans(0xCA83); // FIFO level = 8, 2-SYNC, sync fill, FIFO ena, reset off // ← 1 1 0 0 0 1 0 0 a1 a0 rl1 rl0 st fi oe en 0xC4F7 // 1 1 0 0 0 1 0 0 1 0 0 0 0 0 1 1 0xC483 rf12_trans(0xC483); // AFC if VDI=0, unlimited range, AFC OE+EN // ← 1 0 0 1 1 0 0 mp m3 m2 m1 m0 0 p2 p1 p0 0x9800 // 1 0 0 1 1 0 0 0 0 1 0 1 0 0 0 0 0x9850 rf12_trans(0x9850); // no inv, deviation 90kHz, MAX OUT // ← 1 1 1 r4 r3 r2 r1 r0 m7 m6 m5 m4 m3 m2 m1 m0 0xE196 // 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0xE000 rf12_trans(0xE000); // NOT USE // ← 1 1 0 0 1 0 0 0 d6 d5 d4 d3 d2 d1 d0 en 0xC80E // 1 1 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0xC800 rf12_trans(0xC800); // NOT USE

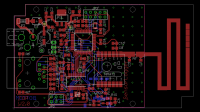

The PCB was matched to the SP 2000 SW housing from STRAPUBOX. So that everything simply fits into SMD components are used where it makes sense.

When it comes to sockets (Power / Ethernet), I'm still a fan of thru-hole - because of the stability. The soldering took place again in the pizza pan as described in the c't Hacks.

The PCB was matched to the SP 2000 SW housing from STRAPUBOX. So that everything simply fits into SMD components are used where it makes sense.

When it comes to sockets (Power / Ethernet), I'm still a fan of thru-hole - because of the stability. The soldering took place again in the pizza pan as described in the c't Hacks.

An antenna must also be connected to the RFM12 module. Usually 1/4 lamba so about 8.3cm. But since there was still space on the PCB, I dared to try a PCB variant in a meandering structure. There is also a nice design note from Texas Instruments (DN024). The result was a bit off, however, because the

An antenna must also be connected to the RFM12 module. Usually 1/4 lamba so about 8.3cm. But since there was still space on the PCB, I dared to try a PCB variant in a meandering structure. There is also a nice design note from Texas Instruments (DN024). The result was a bit off, however, because the of my favorite PCB maker turned out a bit different in reality. The maximum gain was about 790MHz and could then be reduced to 868MHz with a final -6dB gain. This means that reception through concrete ceilings or walls is also feasible.

The software was created with AVR STudio 6 and an AVR-Dragon as a debugger. An UART I/F is on board as support, which then outputs the printf instructions on my MAC via a level converter and the RS232/USB adapter without complaint. A command I/F also allows direct control via the same interface. A small web server is also integrated for normal operation. The entire package including Ethernet and SD support requires approx. 85K FLASH and 12.5K RAM memory.

If you want to try the recording live on my web server: http://vz.rbulla.de. The UUID for the outside temperature (in Langenfeld-Rheinland) is:

If you want to try the recording live on my web server: http://vz.rbulla.de. The UUID for the outside temperature (in Langenfeld-Rheinland) is: e62976c0-7109-11e1-a585-8762f86249c1 .